Construction

Procurement Strategies for Managing Long Lead Items

Procurement Strategies for Managing Long Lead Items

Long lead equipment or items have a delivery time that is long enough it might impact your project's schedule. In order to keep your project on track, it's essential to have a strategy in place to ensure everything shows up when it's supposed to.

Amber Lewey

Originally Published: Jan 26, 2024

Contents

Updated:Nov 19, 2025

First, what are Long Lead Items in Construction?

Long lead items are materials or equipment that require months to years from order to delivery. Long lead items are typically complex goods with many steps in the procurement process. Note: it can also be a more common component or material depending on the current market. These steps typically include at minimum the creation of technical drawings and final client approval.

Long lead items are identified during the planning phase of construction. This ensures that procurement professionals properly evaluate components with extended lead times.

Long lead items will have a significant effect on your project timeline.

For instance, if you do not review and approve the technical drawings according to the schedule, it may delay your order’s arrival to support construction activities. Or, the item can be purchased without the completion of the remainder of the design, meaning you are purchasing at risk. For companies that operate on a project basis, these items are crucial. They can significantly affect the project's delivery timeline and are essential for ensuring timely project completion.

Project contracts stipulate a set delivery date with terms that encourage the contractor to stick to the agreed schedule. Delays, however, can lead to financial repercussions. These may include:

Liquidated damages: If delivery is late, the responsible party may have to pay a penalty. This is often a portion of the contract value.

Delayed Payment Milestones: Payments are typically aligned with delivery milestones. Failure to meet these milestones on time affects when the company can bill the client. While the total payment amount remains unchanged, delayed milestones can significantly disrupt the project's cash flow.

Prioritized Orders: Suppliers may offer quicker delivery for long lead items at an additional cost. This occurs by advancing the order in the queue or opting for faster shipping methods (like air freight instead of sea freight). This expedited delivery incurs additional project costs.

Change Orders: The schedule has to take into account the sequence of events to complete the project, this includes labor and materials/equipment. If the equipment is late but the installing labor wasn’t notified with enough time to try and mitigate, that typically warrants the installers to a change order to address cost incurred and time lost.

Procurement strategies for long lead items that will ensure your project is delivered on time and on budget

The primary cause of cost overruns in projects is inadequate planning. A robust and early plan offers the best opportunity for identification of long lead items, aiding in on-time project delivery.

Step 1: Early Identification

The first step in managing long lead times is to identify potential components that fall into a constrained market category for example, critical electrical equipment. A simpler approach is to list everything that may need to be purchased for your project and use those descriptions to check on availability.

Either way, when recognizing these items early, construction managers can align their work sequences accordingly.

What are some examples of common long lead equipment or items in the construction industry?

List of long lead items in construction:

Integrated equipment such as chillers for data centers, analyzer shelters at processing facilities or custody transfer meters on a pipeline.

Generators and complex electrical equipment such as switchgear, or CAN bus.

Custom fabrications such as staircases, facade structure, or commissioned artwork or installations.

Modules and assemblies such as bathroom modules or integrated HVAC cores

During planning try to specify standard or \"off-the-shelf\" components where possible. Ordering standard components can significantly reduce lead times compared to custom fabrication. If you are unsure where to call this out, most Suppliers are eager to recommend the closest standard option from what detail you do have.

Step 2: Conduct a Risk Assessment

Evaluating risks that could affect the schedule or cost estimates is crucial. This includes considering factors like certification and testing requirements for certain components or specific needs due to the proposed work sequence. Building inventory, purchasing spare parts, and opting for extended warranty and ongoing maintenance services can help mitigate some of your risk as well.

Effective management of long lead items requires a collaborative approach with your supply chain. Procurement should build deep connections with your supply chain to monitor and control the delivery timelines of these items. This ensures that purchase orders are placed ahead of potential risks to arrive when they need to.

Pro Tip: Keep procurement records in single source of truth that all relevant parties have access to. This ensures everyone is working off of the same set of data.

Finally, establish clear and binding agreements with suppliers through purchase orders to prevent misunderstandings. Flexibility can be structured, pursue an agreement that provides incentives for your Suppliers when they are transparent about post purchase thru delivery progress. This will help ensure that delivery schedules are adhered to and if adjustment is needed it is brought up early.

Step 3: Incorporate approvals & deliveries in the project management schedule.

Incorporating the activities prior to a delivery of long lead items into the project schedule is crucial. This allows for a realistic project timeline by capturing the activities where responsibility changes hands gives clarity to longer lead times without compromising the overall plan.

One of the primary challenges is how to ensure timely delivery. Timely delivery is dependent on consistent communication of signals, a signal that the plan had a slight variance. Delays can have a cascading effect on the project schedule and to mitigate this, construction managers should establish contingency plans and lead by example.

When a construction manager has a delay, they have the opportunity to communicate openly and problem solve with the suppliers.

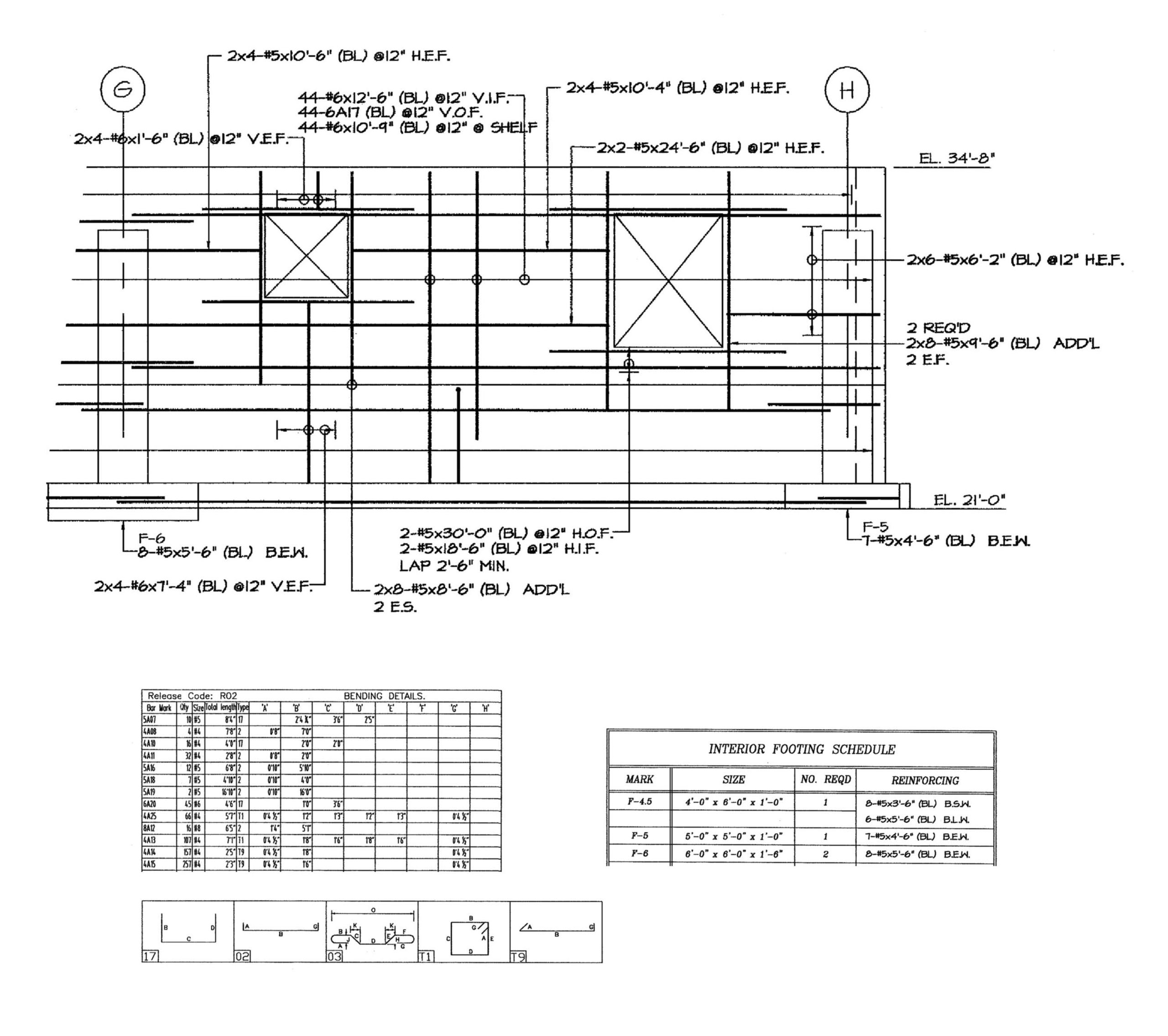

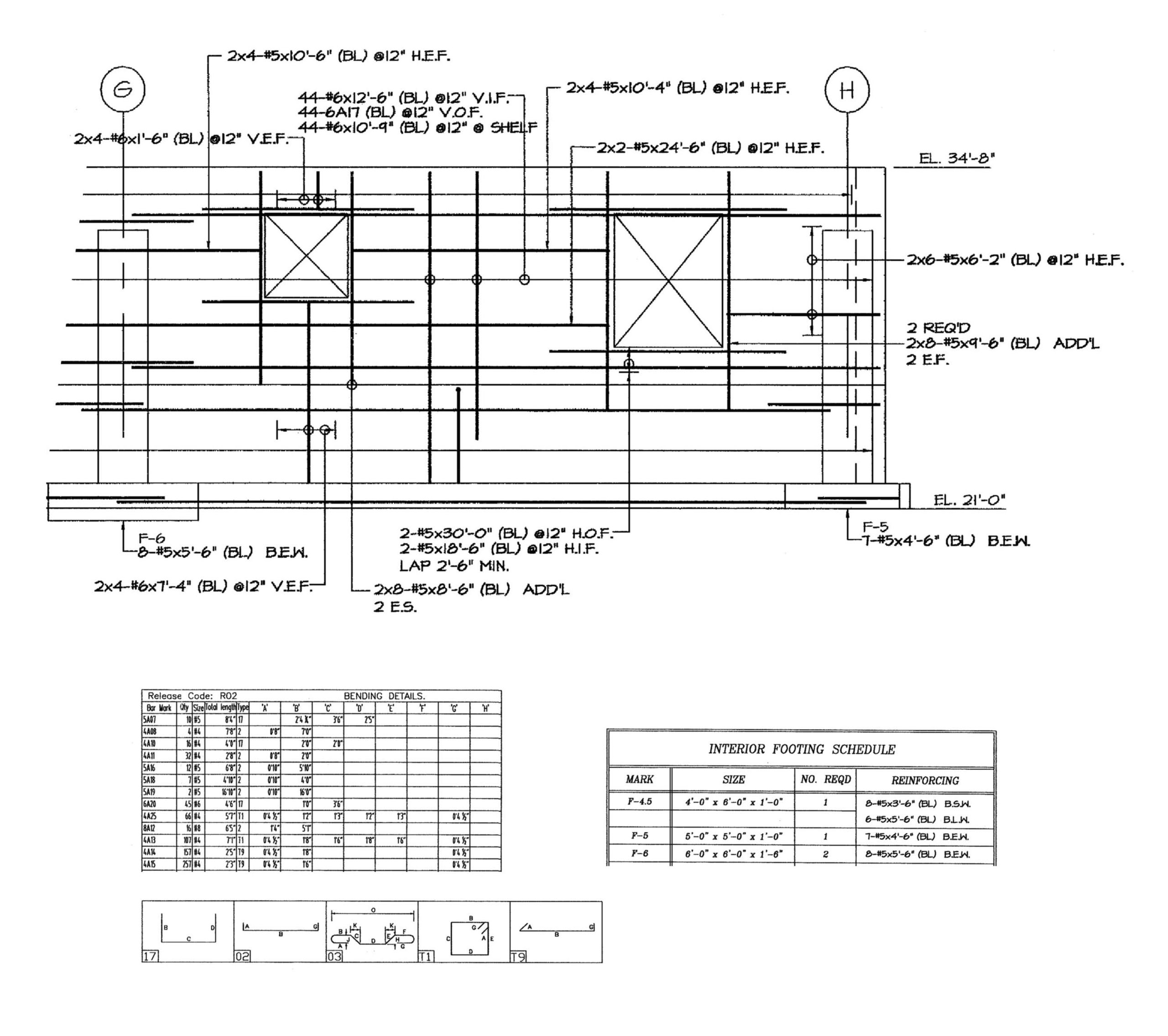

Shop drawings are made after the agreement is executed, and subsequent submittal approvals all require significant coordination. These steps all occur before “lead time” begins and are essential to ensure that the ordered items meet the project’s specifications and requirements and show up on time.

Step 4: Always stay flexible!

Flexibility in the procurement process can be beneficial in managing long lead items. Exploring alternative materials or suppliers might provide solutions when faced with longer lead times. This flexibility can also help in negotiating better terms and ensuring timely delivery.

Conclusion

Take the time early on in the planning process to create the plan to address long lead procurement. Long lead items play a pivotal role in the success of construction projects and other project-based endeavors. Effective management comes through early identification, strategic procurement, and integration into the overall project schedule is essential. By addressing the unique challenges associated with long lead items, you can significantly enhance the likelihood of timely and successful project completion.

First, what are Long Lead Items in Construction?

Long lead items are materials or equipment that require months to years from order to delivery. Long lead items are typically complex goods with many steps in the procurement process. Note: it can also be a more common component or material depending on the current market. These steps typically include at minimum the creation of technical drawings and final client approval.

Long lead items are identified during the planning phase of construction. This ensures that procurement professionals properly evaluate components with extended lead times.

Long lead items will have a significant effect on your project timeline.

For instance, if you do not review and approve the technical drawings according to the schedule, it may delay your order’s arrival to support construction activities. Or, the item can be purchased without the completion of the remainder of the design, meaning you are purchasing at risk. For companies that operate on a project basis, these items are crucial. They can significantly affect the project's delivery timeline and are essential for ensuring timely project completion.

Project contracts stipulate a set delivery date with terms that encourage the contractor to stick to the agreed schedule. Delays, however, can lead to financial repercussions. These may include:

Liquidated damages: If delivery is late, the responsible party may have to pay a penalty. This is often a portion of the contract value.

Delayed Payment Milestones: Payments are typically aligned with delivery milestones. Failure to meet these milestones on time affects when the company can bill the client. While the total payment amount remains unchanged, delayed milestones can significantly disrupt the project's cash flow.

Prioritized Orders: Suppliers may offer quicker delivery for long lead items at an additional cost. This occurs by advancing the order in the queue or opting for faster shipping methods (like air freight instead of sea freight). This expedited delivery incurs additional project costs.

Change Orders: The schedule has to take into account the sequence of events to complete the project, this includes labor and materials/equipment. If the equipment is late but the installing labor wasn’t notified with enough time to try and mitigate, that typically warrants the installers to a change order to address cost incurred and time lost.

Procurement strategies for long lead items that will ensure your project is delivered on time and on budget

The primary cause of cost overruns in projects is inadequate planning. A robust and early plan offers the best opportunity for identification of long lead items, aiding in on-time project delivery.

Step 1: Early Identification

The first step in managing long lead times is to identify potential components that fall into a constrained market category for example, critical electrical equipment. A simpler approach is to list everything that may need to be purchased for your project and use those descriptions to check on availability.

Either way, when recognizing these items early, construction managers can align their work sequences accordingly.

What are some examples of common long lead equipment or items in the construction industry?

List of long lead items in construction:

Integrated equipment such as chillers for data centers, analyzer shelters at processing facilities or custody transfer meters on a pipeline.

Generators and complex electrical equipment such as switchgear, or CAN bus.

Custom fabrications such as staircases, facade structure, or commissioned artwork or installations.

Modules and assemblies such as bathroom modules or integrated HVAC cores

During planning try to specify standard or \"off-the-shelf\" components where possible. Ordering standard components can significantly reduce lead times compared to custom fabrication. If you are unsure where to call this out, most Suppliers are eager to recommend the closest standard option from what detail you do have.

Step 2: Conduct a Risk Assessment

Evaluating risks that could affect the schedule or cost estimates is crucial. This includes considering factors like certification and testing requirements for certain components or specific needs due to the proposed work sequence. Building inventory, purchasing spare parts, and opting for extended warranty and ongoing maintenance services can help mitigate some of your risk as well.

Effective management of long lead items requires a collaborative approach with your supply chain. Procurement should build deep connections with your supply chain to monitor and control the delivery timelines of these items. This ensures that purchase orders are placed ahead of potential risks to arrive when they need to.

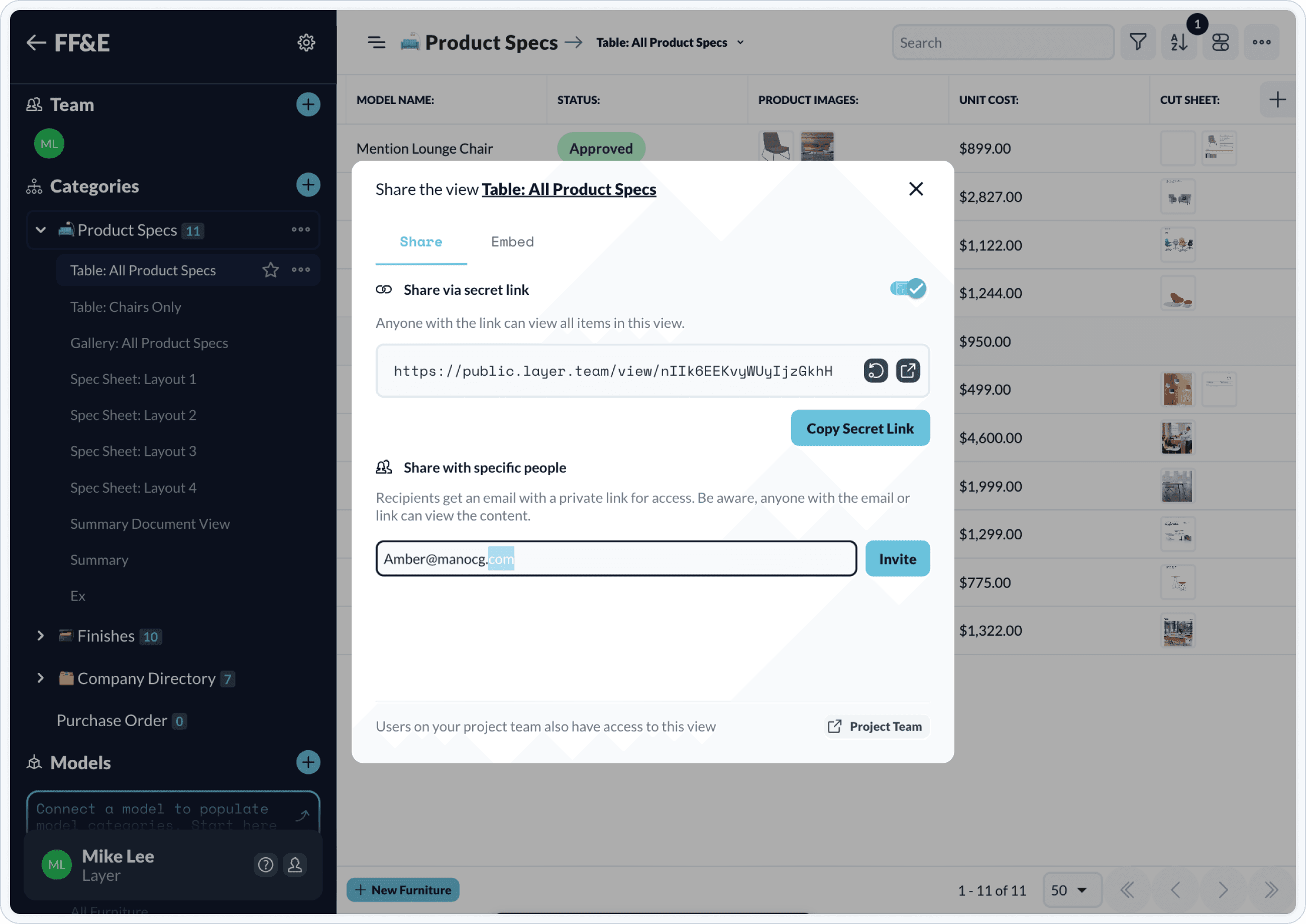

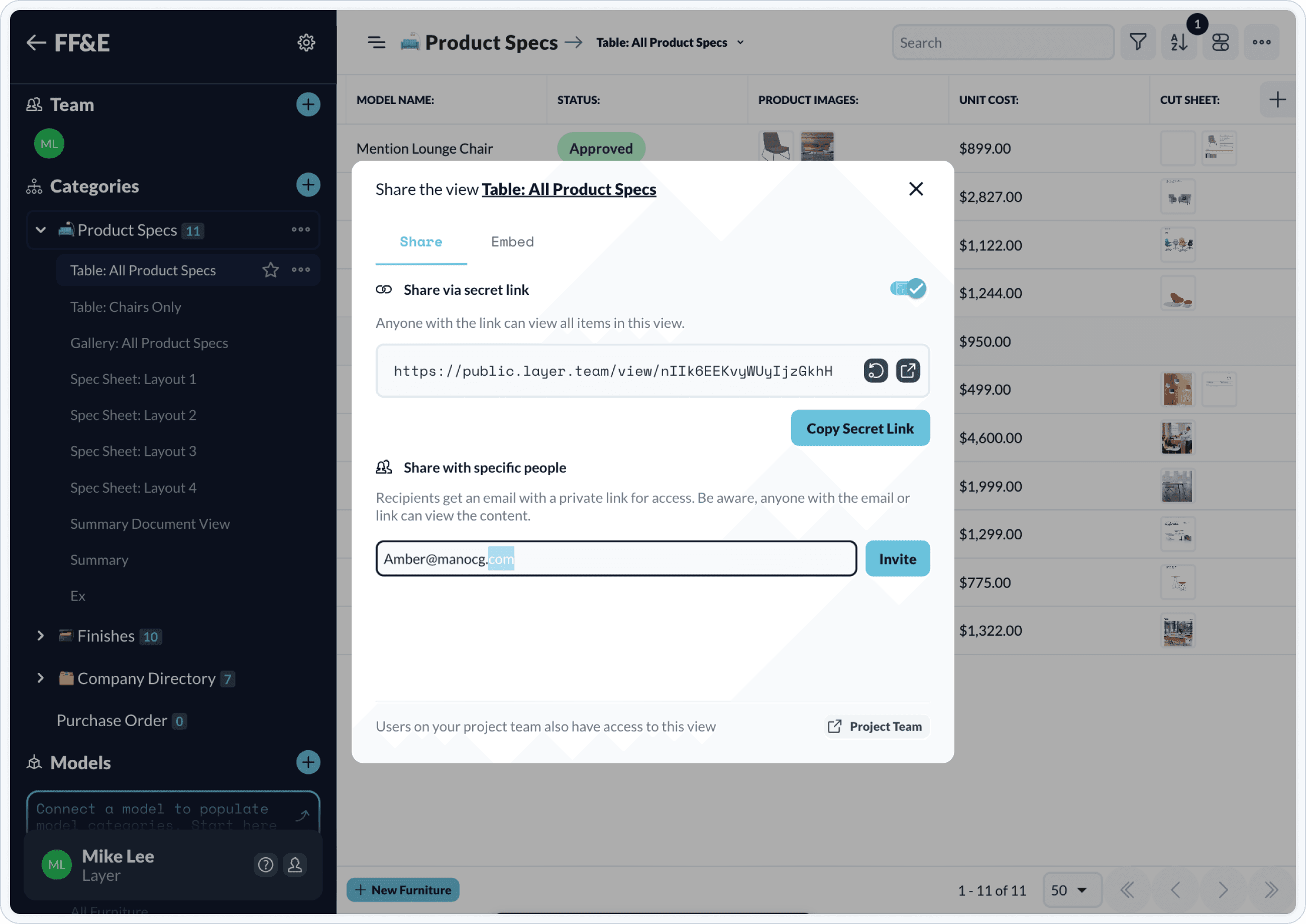

Pro Tip: Keep procurement records in single source of truth that all relevant parties have access to. This ensures everyone is working off of the same set of data.

Finally, establish clear and binding agreements with suppliers through purchase orders to prevent misunderstandings. Flexibility can be structured, pursue an agreement that provides incentives for your Suppliers when they are transparent about post purchase thru delivery progress. This will help ensure that delivery schedules are adhered to and if adjustment is needed it is brought up early.

Step 3: Incorporate approvals & deliveries in the project management schedule.

Incorporating the activities prior to a delivery of long lead items into the project schedule is crucial. This allows for a realistic project timeline by capturing the activities where responsibility changes hands gives clarity to longer lead times without compromising the overall plan.

One of the primary challenges is how to ensure timely delivery. Timely delivery is dependent on consistent communication of signals, a signal that the plan had a slight variance. Delays can have a cascading effect on the project schedule and to mitigate this, construction managers should establish contingency plans and lead by example.

When a construction manager has a delay, they have the opportunity to communicate openly and problem solve with the suppliers.

Shop drawings are made after the agreement is executed, and subsequent submittal approvals all require significant coordination. These steps all occur before “lead time” begins and are essential to ensure that the ordered items meet the project’s specifications and requirements and show up on time.

Step 4: Always stay flexible!

Flexibility in the procurement process can be beneficial in managing long lead items. Exploring alternative materials or suppliers might provide solutions when faced with longer lead times. This flexibility can also help in negotiating better terms and ensuring timely delivery.

Conclusion

Take the time early on in the planning process to create the plan to address long lead procurement. Long lead items play a pivotal role in the success of construction projects and other project-based endeavors. Effective management comes through early identification, strategic procurement, and integration into the overall project schedule is essential. By addressing the unique challenges associated with long lead items, you can significantly enhance the likelihood of timely and successful project completion.

Get Started Today

Want to see how Layer can transform the way your team works?

Get Started Today

Want to see how Layer can transform the way your team works?

Get Started Today

Want to see how Layer can transform the way your team works?

Solutions

Solutions

Solutions