Construction

Why is OFCI so important during Construction Administration?

Why is OFCI so important during Construction Administration?

OFCI, or Owner Furnished Contractor Installed is a sourcing methodology where owners supply materials during a construction project instead of the General Contractor.

Amber Lewey

Originally Published: Jan 3, 2024

Contents

Updated:Nov 19, 2025

With many stakeholders participating in the construction process, coordination of what materials are going where becomes much more difficult. So how do you keep track of it all?

First, what is OFCI?

OFCI is an acronym that stands for Owner Furnished, Contractor Installed. This term refers to any owner supplied equipment or materials that are installed by a contractor. OFCI materials can be anything from specialized equipment such as the machinery in a factory to custom light fixtures. It could also be more mundane materials, such as structural steel or aggregate for site preparation.

Traditionally general contractors are responsible for furnishing the materials and equipment a construction project will consume. However in recent years this trend has changed. Project owners in some industries may prioritize the speed of development over cost or logistical concerns. This is particularly prevalent in the data center space. However other industries such as hospitality, healthcare, and food & beverage may also follow similar expansion strategies.

Why do Owners Choose to Furnish Their Own Equipment?

An owner typically negotiates directly with a supplier to combine buying power and leverage with suppliers across their construction program. Aggregated purchasing results in economies of scale such as reduced costs but also often better lead times. Owners may also negotiate specialized production terms for ofci equipment such as higher quality control procedures or customization options that are not usually available.

On a smaller scale, imagine you own a business such as a restaurant. In order to package to-go orders, you use lots of consumable OS&E items such as napkins and disposable utensils. It doesn't make sense to buy these items every day. Instead you would order larger quantities from a restaurant supply store to lower your operating costs and ensure you always have what you need in stock.

Project owners leverage OFCI Procurement strategies for similar reasons!

So what types of equipment are usually specified as OFCI and what type of projects are you likely to encounter this methodology on? Here are some common examples of equipment owners typically furnish, but then have the Contractor's team install for them:

Data Centers

Hyperscale and Colocation providers both will typically aggregate purchases for long lead equipment. Commonly purchased equipment may include generators, chillers, and other integrated equipment.

Manufacturing

Owners of manufacturing facilities often directly purchase specialized machinery such as tooling or other process equipment.

Residential

On a smaller scale, custom tile, specific fixtures or appliances are all commonly purchased by an owner.

However, these benefits sometimes come with a major drawback. Think about your homebuilding example: If you are rebuilding your kitchen and the tile you ordered does not show up on time you are responsible for any delays!

Liability for successful delivery typically rests with the purchasing party, especially in commercial construction. By "going direct", the the owner usually shifts liability for project completion to themselves.

Effective OFCI management involves collaboration among many parties

Architects and Engineers need to design spaces based on the specifications of the owner-furnished items.

Owners will handle the specification, procurement, logistics, and transportation process. Portions of this may be sub-contracted to a third party such as an owners rep, a 3PL/4PL, or the GC.

General Contractors are responsible for the proper installation and integration of these items into the project.

The crux of successful management of OFCI in construction lies in robust coordination and clear communication among these stakeholders.

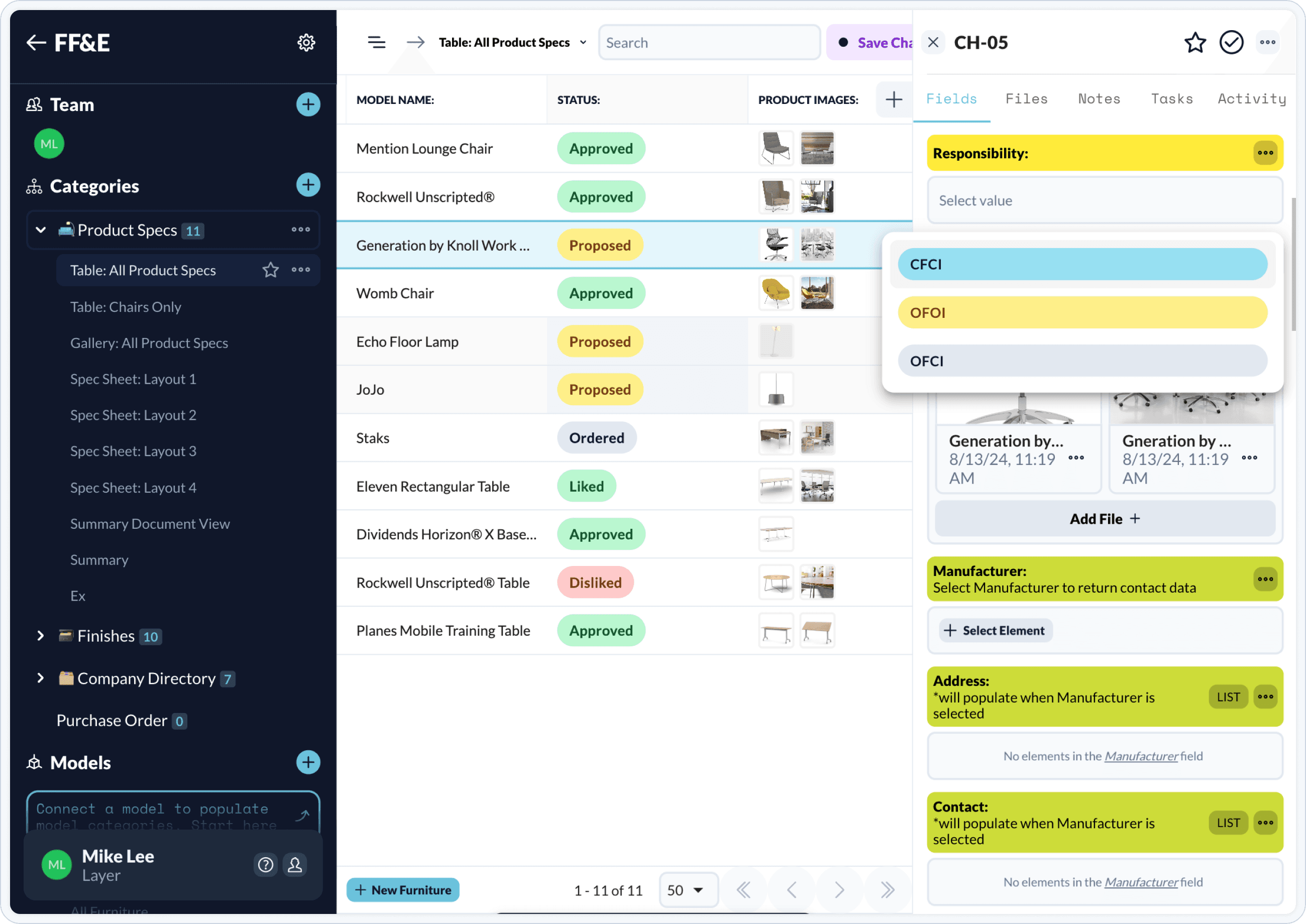

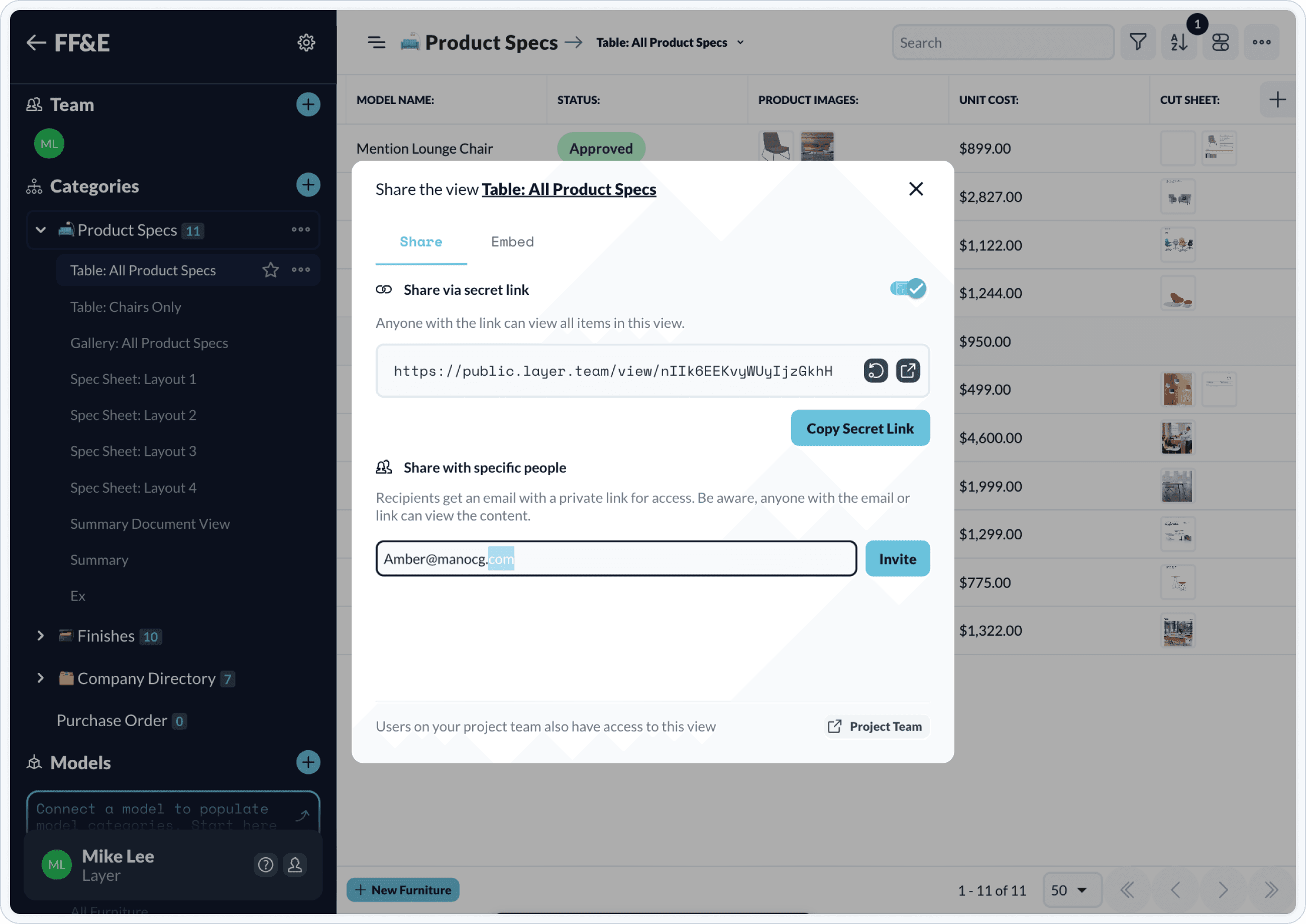

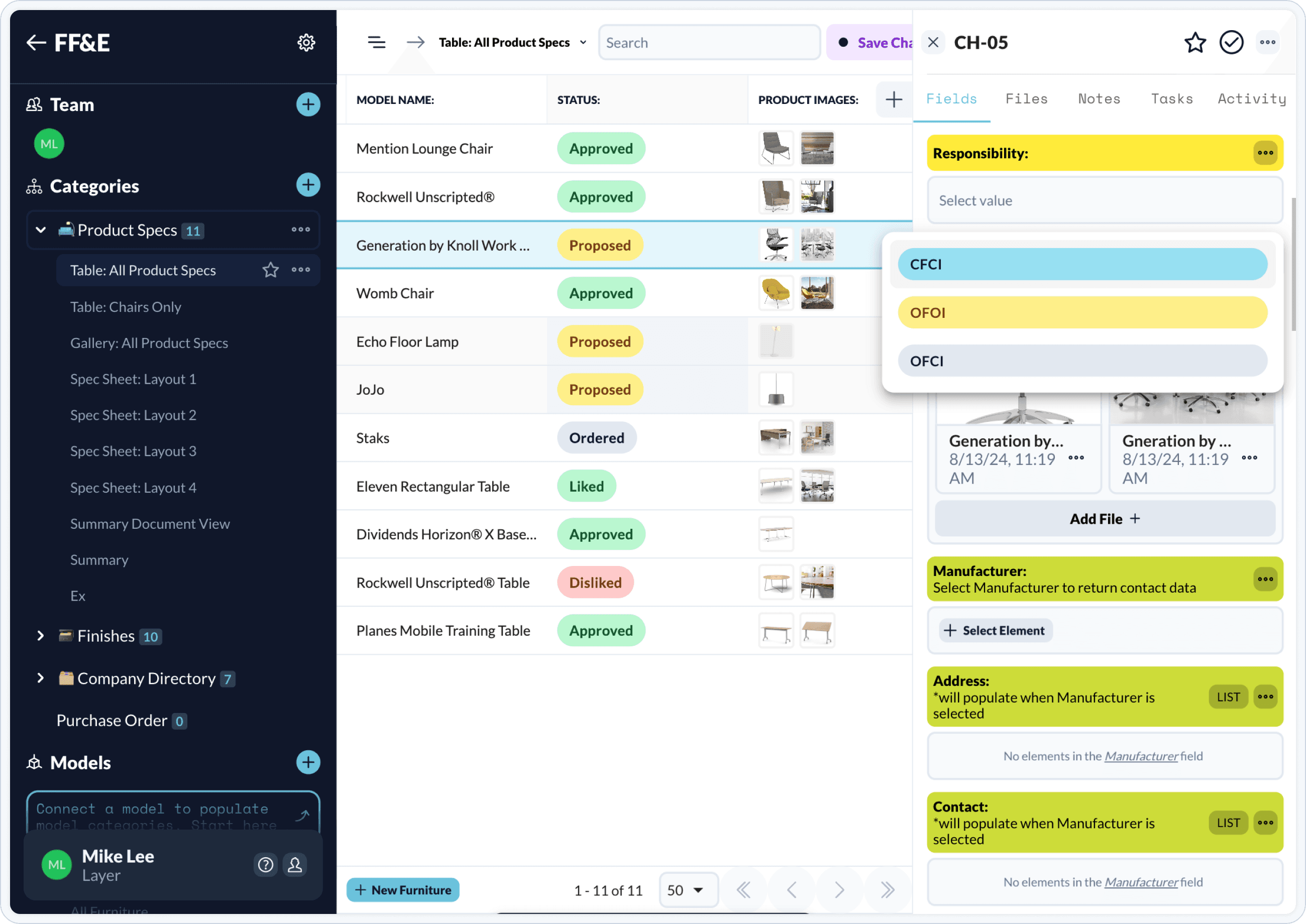

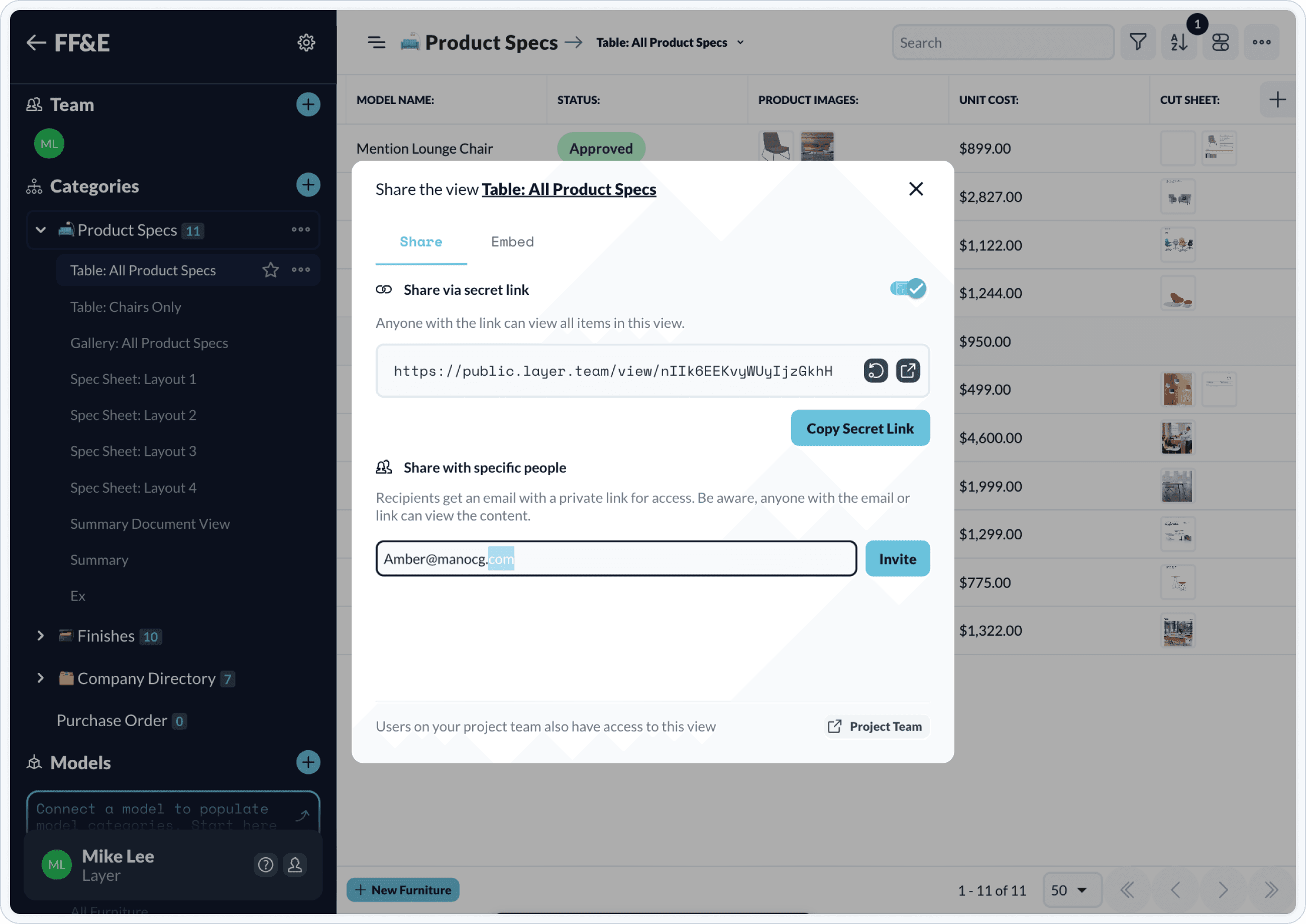

Pro-Tip: When managing OFCI it's important to review your contractual documents carefully. Build a RACI matrix in Layer from this information and use a Shared View to put this information in the right hands.

If a specified piece of equipment experiences a production delay, it can cause a large schedule delay. Worse, delays can cascade across the project if there is more than one dependency on the material. Transparent communication between the owner's procurement team and the GC & Construction Administration teams is essential.

So, as a Construction Administration Professional, how can you best work with the Owner's Procurement Team to ensure your project is delivered on-time?

Before starting a project with extensive OFCI, you should ask yourself these high level questions:

1. Who will manage the overall process?

Various individuals will be involved in procurement, placing orders, and logistics. It's essential to have smooth coordination between all parties as well as a single source of truth shared between teams. Ensure you have adequate resources for effective coordination of these tasks.

Pro-Tip: Use a platform like Layer to manage OFCI all tied directly to Revit models

2. How are you planning the work sequencing or project timeline?

For optimal efficiency and cost reduction, the alignment of delivery and installation dates with other project phases is vital. Assign someone to oversee the schedule to prevent delays and budget excesses. Having an alternative equipment sources as a contingency plan is advisable in case of unforeseen issues.

3. What's your strategy for transportation and storage?

Organize for the required tools and materials to be shipped to the site. Failure to synchronize delivery dates or unexpected construction and transportation setbacks could result in a need for storage solutions for the incoming supplies. Maintain clear communication and closely monitor the schedule to avert delivery challenges.

Once you can answer these questions, you're ready to start building the workflows and processes your project will rely on!

Remember, disconnected data and communications processes are your enemy. Keeping everyone on the same page is key to successful execution. Project overruns will cost you, both literally and figuratively. Sticking to your project milestones is essential for your organization to stay profitable.

With many stakeholders participating in the construction process, coordination of what materials are going where becomes much more difficult. So how do you keep track of it all?

First, what is OFCI?

OFCI is an acronym that stands for Owner Furnished, Contractor Installed. This term refers to any owner supplied equipment or materials that are installed by a contractor. OFCI materials can be anything from specialized equipment such as the machinery in a factory to custom light fixtures. It could also be more mundane materials, such as structural steel or aggregate for site preparation.

Traditionally general contractors are responsible for furnishing the materials and equipment a construction project will consume. However in recent years this trend has changed. Project owners in some industries may prioritize the speed of development over cost or logistical concerns. This is particularly prevalent in the data center space. However other industries such as hospitality, healthcare, and food & beverage may also follow similar expansion strategies.

Why do Owners Choose to Furnish Their Own Equipment?

An owner typically negotiates directly with a supplier to combine buying power and leverage with suppliers across their construction program. Aggregated purchasing results in economies of scale such as reduced costs but also often better lead times. Owners may also negotiate specialized production terms for ofci equipment such as higher quality control procedures or customization options that are not usually available.

On a smaller scale, imagine you own a business such as a restaurant. In order to package to-go orders, you use lots of consumable OS&E items such as napkins and disposable utensils. It doesn't make sense to buy these items every day. Instead you would order larger quantities from a restaurant supply store to lower your operating costs and ensure you always have what you need in stock.

Project owners leverage OFCI Procurement strategies for similar reasons!

So what types of equipment are usually specified as OFCI and what type of projects are you likely to encounter this methodology on? Here are some common examples of equipment owners typically furnish, but then have the Contractor's team install for them:

Data Centers

Hyperscale and Colocation providers both will typically aggregate purchases for long lead equipment. Commonly purchased equipment may include generators, chillers, and other integrated equipment.

Manufacturing

Owners of manufacturing facilities often directly purchase specialized machinery such as tooling or other process equipment.

Residential

On a smaller scale, custom tile, specific fixtures or appliances are all commonly purchased by an owner.

However, these benefits sometimes come with a major drawback. Think about your homebuilding example: If you are rebuilding your kitchen and the tile you ordered does not show up on time you are responsible for any delays!

Liability for successful delivery typically rests with the purchasing party, especially in commercial construction. By "going direct", the the owner usually shifts liability for project completion to themselves.

Effective OFCI management involves collaboration among many parties

Architects and Engineers need to design spaces based on the specifications of the owner-furnished items.

Owners will handle the specification, procurement, logistics, and transportation process. Portions of this may be sub-contracted to a third party such as an owners rep, a 3PL/4PL, or the GC.

General Contractors are responsible for the proper installation and integration of these items into the project.

The crux of successful management of OFCI in construction lies in robust coordination and clear communication among these stakeholders.

Pro-Tip: When managing OFCI it's important to review your contractual documents carefully. Build a RACI matrix in Layer from this information and use a Shared View to put this information in the right hands.

If a specified piece of equipment experiences a production delay, it can cause a large schedule delay. Worse, delays can cascade across the project if there is more than one dependency on the material. Transparent communication between the owner's procurement team and the GC & Construction Administration teams is essential.

So, as a Construction Administration Professional, how can you best work with the Owner's Procurement Team to ensure your project is delivered on-time?

Before starting a project with extensive OFCI, you should ask yourself these high level questions:

1. Who will manage the overall process?

Various individuals will be involved in procurement, placing orders, and logistics. It's essential to have smooth coordination between all parties as well as a single source of truth shared between teams. Ensure you have adequate resources for effective coordination of these tasks.

Pro-Tip: Use a platform like Layer to manage OFCI all tied directly to Revit models

2. How are you planning the work sequencing or project timeline?

For optimal efficiency and cost reduction, the alignment of delivery and installation dates with other project phases is vital. Assign someone to oversee the schedule to prevent delays and budget excesses. Having an alternative equipment sources as a contingency plan is advisable in case of unforeseen issues.

3. What's your strategy for transportation and storage?

Organize for the required tools and materials to be shipped to the site. Failure to synchronize delivery dates or unexpected construction and transportation setbacks could result in a need for storage solutions for the incoming supplies. Maintain clear communication and closely monitor the schedule to avert delivery challenges.

Once you can answer these questions, you're ready to start building the workflows and processes your project will rely on!

Remember, disconnected data and communications processes are your enemy. Keeping everyone on the same page is key to successful execution. Project overruns will cost you, both literally and figuratively. Sticking to your project milestones is essential for your organization to stay profitable.

Get Started Today

Want to see how Layer can transform the way your team works?

Get Started Today

Want to see how Layer can transform the way your team works?

Get Started Today

Want to see how Layer can transform the way your team works?

Solutions

Solutions

Solutions